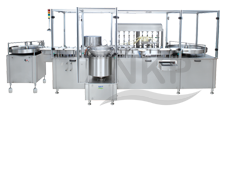

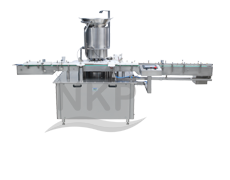

Injectable Dry Powder Filling with Rubber Stoppering Machine for Vials

Automatic injectable dry powder filling machine is a highly compact and durable machine that is employed for filling dry powder into vials and then placing a rubber stopper on its top to prevent leakages of any sort. The fact that the dry powder filler machine is capable of performing two operations of filling and putting rubber stoppers simultaneously, makes it quite an effective piece of machinery for pharmaceutical industries.

Dry powder filling machine has an air requirement of 6Kg/cm2 for carrying out the operations and needs an electric supply of 7 HP. The fill size obtained through the machine can differ from 50 mg to 6 gm by accommodating vial sizes having capacity between 5 ml. to 100ml. The sizes of rubber stopper that are within the permissible range of injectable filling machine are 20 mm, 28 mm & 32 mm.