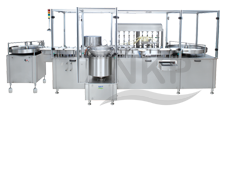

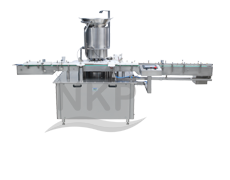

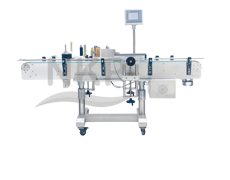

Labeling Machine - Automatic Self Adhesive Vertical Labelling Machine

ATL- 120 and ATL- 250, the two variants of automatic self-adhesive vertical labelling machine, are used to wrap the containers with labels. These label stickers show important information regarding the product and are quite an important piece of machinery for pharmaceutical companies. Both Vertical labeling machines are manufactured using premium grade raw material that imparts them a sturdy build. It is very important for the labeling machines to have a strong structure as the long hour and fast operations require durability. The pharmaceutical is the industry where these labelling machines enjoy extensive application. Self adhesive labeling machine or self adhesive labeler is one of the most preferred labelling machines for round containers by partially or fully wrapping it around. It has a higher production rate than compared to other machines and applies the label neatly on the round containers with high precision. The vertical sticker labeling machine is also one of the machines, preferred for labeling round containers. It is easier to accommodate bottles of varying diameter with the vertical sticker labelling machine thus providing ease of compatibility.

The electricity requirement for both the machines is 2.5 HP and the minimum gap between the two labels is kept 5 mm. The production rate of ATL-120 is 120 vials/min and that of ATL- 250 is up to 240 vials/min. This self-adhesive vial labeling machine can accommodate containers having diameter between 20 mm to 90 mm. The conveyor height can be adjusted from 850 to 900 mm can thus allow wide applications. NKP Pharma supplies the labelling machine at an attractive price range and promises to deliver quality services. The machines are very durable and require low maintenance.