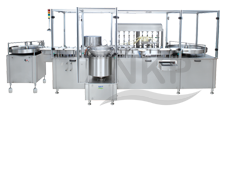

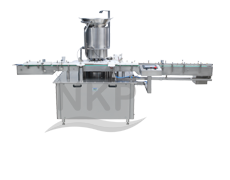

ROPP Capping Machine - Monoblock Dry Syrup Powder Filling with ROPP Cap Sealing Machine

Automatic monoblock dry syrup powder filling machine with eight head ROPP cap sealing is a very useful machine for numerous pharmaceutical industries as it performs multiple operation of powder filling and sealing the bottle. The bottles, after being washed thoroughly, are passed through conveyor to the dry syrup powder filling station. At this station, the bottle is filled up with dry syrup powder. The bottles filled with powder are then passed to the ROPP capping station where caps are placed over the bottles in order to seal them. The ROPP capping machine is used in the pharmaceutical industries in order to protect the containers from being contaminated. A ROPP cap sealing machine applies Roll on Pilfer Proof (ROPP) or aluminum metal caps on the bottles or containers. Various size of containers having round, oval, square, and rectangular containers can be accommodated in the ROPP cap sealer machine. Apart from pharmaceutical industries, a ROPP capper machine finds application in packaging containers or bottles for beverages, wine, and distilleries. The machine has quite a sturdy structure that deems it suitable to be operated for prolonged duration.

Dry syrup filling machine requires an electric supply of 5.25 HP and incorporates bottles having capacity between 15 ml to 250 ml. The cap sizes, used in ROPP cap sealing machine, are 22mm, 25mm, 28mm. The production rate of the machine is up to 100 to 120 bottles per minute.