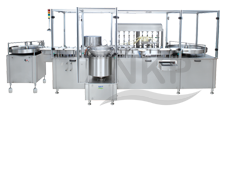

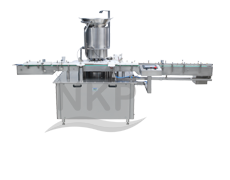

Automatic Injectable Dry Powder Filling With Rubber Stoppering Machine

The NKPF-250 D, a variant of automatic injectable dry powder filling machine with rubber stoppering, boasts of improved performance and high production rates. It performs very precise operations having an accuracy of �1%. This accuracy is dependent on the consistency and the uniformity of bulk density of injectable powder under controlled humidity level.

The production rate of NKPF-250D dry powder filling machine shows an increased value as compared to some of the other variants. The powder filler has a rate of 240 fills/min for single dose and 120 fills/min for a double dose. For a triple dose, the machine is capable of doing 80 fills/min whereas for four dose, it is 60 fills/min. The conveyor height can be adjusted from 900 to 950 mm and the vial sizes ranging from 5 ml to 30 ml can be incorporated with the powder filling machine.